Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

Feature of Our Aluminum laser Cutting machine

1. CNC Gantry Machine with Robust Welded Body. Following annealing at high temperatures and precise machining using a large CNC milling machine, it exhibits excellent stiffness and steadiness.

2. Utilizes high-quality imported linear guide rail drive for superior rigidity and stability.

3. Features an aluminum beam that undergoes advanced heat treatment for strength, lightweight, and rigidity.

4. Fiber laser offers numerous benefits including top-notch beam quality, brightness, efficiency, low maintenance, and reliable operation at a low cost and compact size.

5. Equipped with servo motor, driver, and Italy Reducer for high-speed and powerful performance.

3000w laser cutting machine Advantage

1.Precision Cutting: The laser cutting machine offers a positioning accuracy of 0.05mm and a repeated positioning accuracy of 0.03mm.

2. Fine Cuts with Laser Technology: Laser beams are focused into tiny points of light, creating high power density at the focal point. This rapidly heats the material to vaporization, forming narrow slits typically 0.10 to 0.20mm wide as the beam moves along the material.

3. Smooth Cutting Surface: Laser cutting results in a clean cut without any burrs, with the surface roughness of the incision usually kept within Ra6.5.

4. High Speed Performance: Laser cutting machines can achieve cutting speeds of up to 15m/min, with a maximum positioning speed of 30m/min, significantly faster than wire cutting.

5. Superior Cutting Quality: Laser cutting offers precise, non-contact cutting with minimal heat impact on the edges. This helps prevent thermal deformation of the workpiece, eliminating the edge collapse often seen in traditional material cutting methods. The cutting seam is typically of high quality.

New Design Laser Cutting Machine Parameter

Model | BKJ-F-3015S | BKJ-F-4015S | BKJ-F-4020S | BKJ-F-6015S | BKJ-F-6020S | BKJ-F-6025S | BKJ-F-8025S |

Working Area | 3050×1530mm | 4050×1530mm | 4050×2030mm | 6050×1530mm | 6050×2030mm | 6050×2530mm | 8050×2530mm |

Power | 1500W/2000W/3000W/4000W/6000W/8000W/12000W | ||||||

Positioning Accuracy | 0.03mm | ||||||

Repeated Positioning Accuracy | 0.02mm | ||||||

Max.Moving Speed | 100m/min | 100m/min | 120m/min | 100m/min | 120m/min | 120m/min | 120m/min |

2000W Fiber Laser Cutting Machine Application:

Fiber laser cutting machines are advanced technology products with a wide range of uses:

1. Automotive sector: cutting car doors, bodies, floors, engine covers, rear covers, and other components.

2. Hardware industry: bathroom fixtures, hotel hardware, decorative hardware, and crafts.

3. Kitchenware production: meeting customized production needs, whether for mass production or small batches.

4. Sheet metal processing: replacing traditional cutting methods and becoming the primary cutting equipment.

5. Advertising sector: meeting cutting needs for various complex fonts due to high customization demands and low efficiency of traditional methods.

6. Fitness equipment manufacturing: cutting and punching round tubes, square tubes, oval tubes, D-shaped tubes, and other shapes.

7. Home appliance and kitchenware industry: improving speed and yield rate of new product development through thin plate processing.

8. Agricultural machinery sector: efficient processing of sheet metal parts to improve production efficiency and reduce costs.

9. Engineering machinery industry: used for circular hole cutting to improve labor productivity.

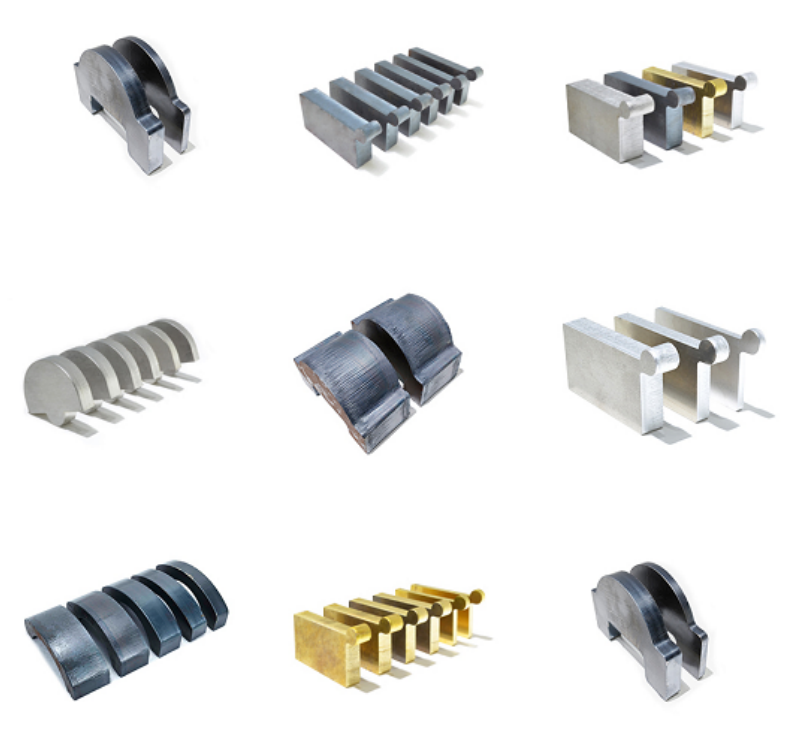

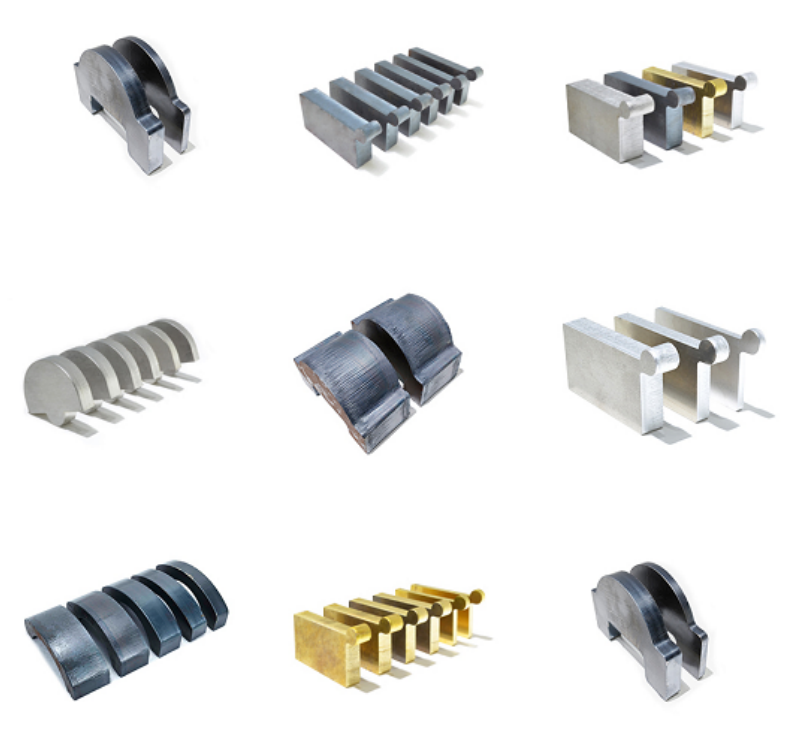

sample pictures of Fiber laser cutting machine for aluminum

If you want to know more details about our laser, welcome leave your information, i will send you quotation soon

Feature of Our Aluminum laser Cutting machine

1. CNC Gantry Machine with Robust Welded Body. Following annealing at high temperatures and precise machining using a large CNC milling machine, it exhibits excellent stiffness and steadiness.

2. Utilizes high-quality imported linear guide rail drive for superior rigidity and stability.

3. Features an aluminum beam that undergoes advanced heat treatment for strength, lightweight, and rigidity.

4. Fiber laser offers numerous benefits including top-notch beam quality, brightness, efficiency, low maintenance, and reliable operation at a low cost and compact size.

5. Equipped with servo motor, driver, and Italy Reducer for high-speed and powerful performance.

3000w laser cutting machine Advantage

1.Precision Cutting: The laser cutting machine offers a positioning accuracy of 0.05mm and a repeated positioning accuracy of 0.03mm.

2. Fine Cuts with Laser Technology: Laser beams are focused into tiny points of light, creating high power density at the focal point. This rapidly heats the material to vaporization, forming narrow slits typically 0.10 to 0.20mm wide as the beam moves along the material.

3. Smooth Cutting Surface: Laser cutting results in a clean cut without any burrs, with the surface roughness of the incision usually kept within Ra6.5.

4. High Speed Performance: Laser cutting machines can achieve cutting speeds of up to 15m/min, with a maximum positioning speed of 30m/min, significantly faster than wire cutting.

5. Superior Cutting Quality: Laser cutting offers precise, non-contact cutting with minimal heat impact on the edges. This helps prevent thermal deformation of the workpiece, eliminating the edge collapse often seen in traditional material cutting methods. The cutting seam is typically of high quality.

New Design Laser Cutting Machine Parameter

Model | BKJ-F-3015S | BKJ-F-4015S | BKJ-F-4020S | BKJ-F-6015S | BKJ-F-6020S | BKJ-F-6025S | BKJ-F-8025S |

Working Area | 3050×1530mm | 4050×1530mm | 4050×2030mm | 6050×1530mm | 6050×2030mm | 6050×2530mm | 8050×2530mm |

Power | 1500W/2000W/3000W/4000W/6000W/8000W/12000W | ||||||

Positioning Accuracy | 0.03mm | ||||||

Repeated Positioning Accuracy | 0.02mm | ||||||

Max.Moving Speed | 100m/min | 100m/min | 120m/min | 100m/min | 120m/min | 120m/min | 120m/min |

2000W Fiber Laser Cutting Machine Application:

Fiber laser cutting machines are advanced technology products with a wide range of uses:

1. Automotive sector: cutting car doors, bodies, floors, engine covers, rear covers, and other components.

2. Hardware industry: bathroom fixtures, hotel hardware, decorative hardware, and crafts.

3. Kitchenware production: meeting customized production needs, whether for mass production or small batches.

4. Sheet metal processing: replacing traditional cutting methods and becoming the primary cutting equipment.

5. Advertising sector: meeting cutting needs for various complex fonts due to high customization demands and low efficiency of traditional methods.

6. Fitness equipment manufacturing: cutting and punching round tubes, square tubes, oval tubes, D-shaped tubes, and other shapes.

7. Home appliance and kitchenware industry: improving speed and yield rate of new product development through thin plate processing.

8. Agricultural machinery sector: efficient processing of sheet metal parts to improve production efficiency and reduce costs.

9. Engineering machinery industry: used for circular hole cutting to improve labor productivity.

sample pictures of Fiber laser cutting machine for aluminum

If you want to know more details about our laser, welcome leave your information, i will send you quotation soon

content is empty!